Iron ore pellets and Pelletizing processes |

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh ...

IRON ORE—2002 1References that include a section mark (§) are found in the Internet References Cited section. IRON ORE By William S. Kirk

pelletizing iron ore process Pelletizing Wikipedia . Pelletizing is the process of compressing or molding a material into the shape of a pellet.

Report of Investigations 9230 Effectiveness of Organic Binders for Iron Ore Pelletization By Larry A. Haas, Jeffrey A. Aldinger, and Robert K. Zl

: Use of Boron Based Binders in Pelletization of Iron Ores: Alternative Binders to Bentonite for Iron Ore Pelletization (): Osman Sivrikaya: Books

NEED FOR BENEFICIATION High grade iron ore less than 10% of the total reserves. ROM iron ore with Fe less than 58 – 60% discarded as waste. After beneficiation iron ...

Iron ore pelletizing zenith. Iron ore fines are agglomerated into pellets and then indurated using a furnace ... This process generates iron ore filter cake which ...

IRON ORE PELLETIZATION. VOL. 58 NO. 7. IRON STEEL REVIEW | 192 | DECEMBER 2014. Introduction. India is fortunate regarding huge resources of iron ore.

Iron Ore Pelletization | VT Corp Pvt Ltd. The process of pelletization enables converting Iron Ore Fines into "Uniformed Sized Iron Ore Pellets" that can be ...

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size

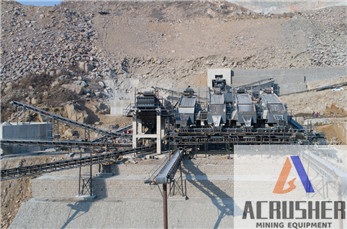

Iron Ore,Ore Processing,Ore Beneficiation,Mining . Iron Ore Mining Solution is supported here while SBM Mining Machinery is focusing on Iron Ore Beneficiation and ...

Iron ore pellets are spheres of typically 818mm ( inch) to be used as raw material for blast furnace. They typically contain 6772% Fe and various ...

Pelletization is one of useful processes for the agglomeration of iron ore or concentrates. However, manganese ore fines are mainly agglomerated by sintering due to ...

Outokumpu Technology Pelletizing technologies for iron ore Outokumpu Technology offers unrivalled solutions for processing iron ores. These include

Induration Machine for Iron Ore Pelletizing Plant . Ball mill WetGrinding System Equipment for Pelletizing Plants . This pelletizing plant receives iron ore.

The pelletization of fine powder plays an important role in industry, ... The pellets of iron ore concentrates have been found to be an excellent feed for

The aim of this workis to study the pelletization the ElBaria Oasis iron ore with waste pellets present in ElDekhilla

Vale is the world''s leading producer of iron ore and pellets

CP Kelco is a leading provider for mining froth flotation and pelletization aids. ... Iron ore pellets are produced for easier handling and transportation.

Balling Disc In Pelletization Of Iron Ore Process. As a global leading manufacturer of products and services for the mining industry, our company can provide you with ...

SUSTAINABILITY IN PELLETIZING IRON ORE THROUGH THE . beneficiation, Hatch technology selection and process definition in the design of pellet

Iron Ore Pelletization Technology and its Environmental Impact Assessment in Eastern Region of India – A Case Study ☆

Jan 07, 2012· Video embedded· Sliding problem during pelletization of iron fines.

IRON ORE FINES UTILIZATION via PELLETIZATION World Wide Trend for Blast Furnace Burden Availability and Cost are the major factors. Lump Ore and ...